If you already have an existing account with another Cat App, you can use the same account to sign in here

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

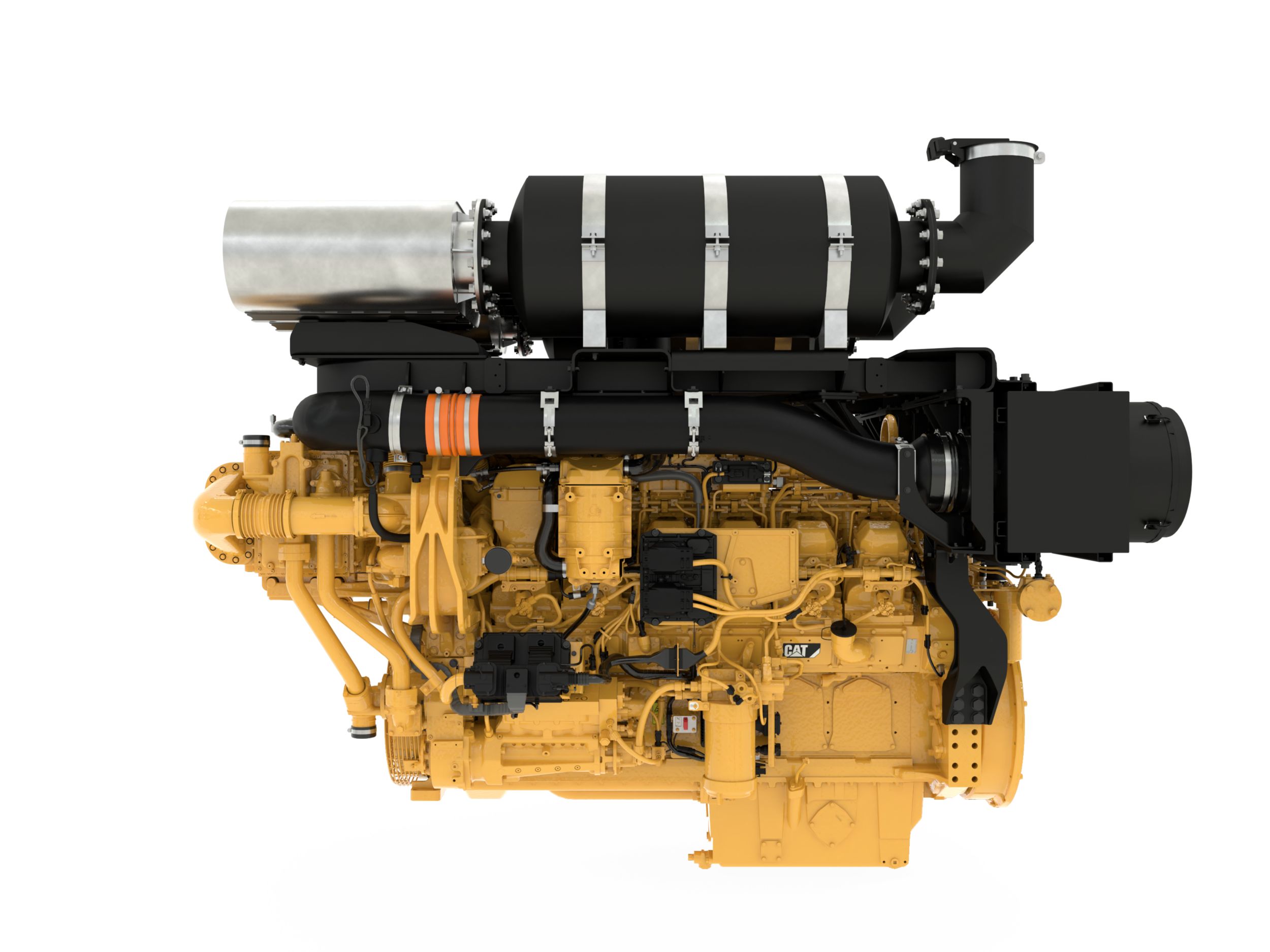

DGB™: Three Letters Making A Big Difference

DUAL-FUEL TECHNOLOGY DRIVES DOWN EMISSIONS & FUEL COSTS

Over the last few decades, engine manufacturers — Caterpillar included — have made big strides in reducing the emissions their products generate. Just think about the car or truck you drive today, and compare it to the one you (or your parents) drove back in the 1970s or ‘80s. We’ve come a long way.

The same is true in oil and gas, where emission standards worldwide continue to get more stringent. Our customers are committed to reducing their environmental footprint, with many working toward a carbon-neutral future. Still, they don’t want and shouldn’t have to sacrifice quality, reliability or durability to get there.

Enter DGB™

At Cat® Oil & Gas, we’ve introduced a number of products and technologies to help our customers reduce emissions. One of the most game-changing new solutions is something called DGB, short for Dynamic Gas Blending™.

How DGB works is complicated, but what it does is simple: It allows our customers to lower their fuel costs and greenhouse gas (GHG) emissions without giving up any power, performance, reliability or ease of maintenance. That’s a big reason our 3512E Tier 4 Final DGB Well Service Engine took home “Engine of the Year” honors in 2019 from Diesel Progress.

Runs on way more than diesel

To dive into the details, a DGB engine is a “dual-fuel” product. That means that even though it’s built on a traditional diesel engine platform and can operate on diesel fuel, it can also run on a variety of other fuels that cost less and generate fewer emissions than diesel — compressed natural gas, liquid natural gas, pipeline gas and field gas, for example.

That last one, field gas, is especially important. Sometimes, when companies are extracting oil and gas from the ground, other unwanted gases escape into the atmosphere. That’s called gas flaring. If you’ve ever driven by an oil and gas site, you might have seen these flares shooting up from pipes in the ground. They’re estimated to contribute 9% of the industry’s total GHG emissions.

Our DGB technology lets customers run their engines on this flared gas — which not only keeps the emissions out of the air but is available essentially free of charge.

Drives fuel costs way down

Saving money’s always a focus for our customers, and that’s another reason they love DGB engines. Our 3512E Tier 4 Final DGB Engine can achieve up to 85% diesel displacement. That’s a fancy way of calculating the volume of fuel an engine uses, and in the case of the 3512E, it can use as little as 15% diesel and as much as 85% of other, less expensive fuels. You can see where that could lead to big bottom-line savings.

There’s a lot more to learn about DGB engines, so if you’re interested in the specifics be sure to check out our DGB website, where you’ll find a number of articles and videos that explain its technologies and benefits in greater detail. And if you want to know more about all we’re doing in the oil and gas industry, visit our website or follow us on Facebook, Twitter or LinkedIn.

Related Articles

-

Curious About E-Frac? Here Are Three Factors To Consider.

With proponents of electric fracking claiming cost savings of $1 million a month, it’s easy to get caught up in the hype. But take a careful look at the numbers to see if those savings are a reality for your operation.

Learn More -

Technology Delivers High Displacement and Low Emissions

With our 3512E Tier 4 Final DGB™ engine, you get industry-best diesel displacement, fuel flexibility and GHG reductions. How? Thanks to these industry-first technologies.

Learn More