If you already have an existing account with another Cat App, you can use the same account to sign in here

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

Waste You’ll Want to Hold Onto: Biogas and Its Benefits

Unlocking Biogas Success: 25 Years of Expert Advice on Benefits and Challenges

By Marty Hopkins, Sales Representative- Biogas, Natural Gas, and CHP Applications, Peterson Cat | Posted: April, 2025

As more people turn to biogas, demand isn’t just growing - it’s thriving. Capital investment jumped 40% between 2023 and 2024, according to the American Biogas Council, and close to 2,500 U.S. facilities are now capturing and using biogas. Nearly half are at wastewater treatment plants and close to a quarter at landfills.

What should you keep in mind if you’re thinking about a biogas project on your site? To get answers, we sat down with an expert — Marty Hopkins of Cat® dealer Peterson Cat. He’s spent 25+ years in the power generation business, with the last 15 focused almost exclusively on biogas. Here’s what he had to tell us:

Why are biogas projects getting more popular? What are the biggest advantages?

Marty: There are three benefits that really stand out:

- Reliability. Solar panels require the sun, and wind turbines require the wind. But landfills and wastewater treatment plants produce biogas 24/7, regardless of weather or other external factors. It’s a continuous source of renewable energy you can put toward your operation’s baseload.

- Cost Savings. By capturing and utilizing biogas, you can reduce your reliance on the grid, lower long-term energy costs, and even generate revenue - for example, selling surplus energy back to the market. You’re turning what was once wasted into a valuable resource.

- Environmental impact. Using biogas as your energy source can help reduce a site’s total greenhouse gas emissions

For wastewater plants, I’d add a fourth: heat production. Heat is a natural byproduct of using an engine to convert biogas to electricity. You can pump that heat back into the digester to save even more on energy costs.

Sounds great, but what’s the catch? What’s the biggest challenge with biogas projects?

Marty: The condition of the gas itself. Biogas is full of contaminants like sulfur and siloxanes. Without treatment, they can eat away at the metals in an engine — which over time leads to performance issues, downtime and added costs. You either need to clean the gas upfront or plan for extra engine maintenance along the way.

Location plays a role in that decision. To comply with certain emissions regulations, you may need to consider aftertreatment, but for that system to work properly, you’ll need to clean the biogas.

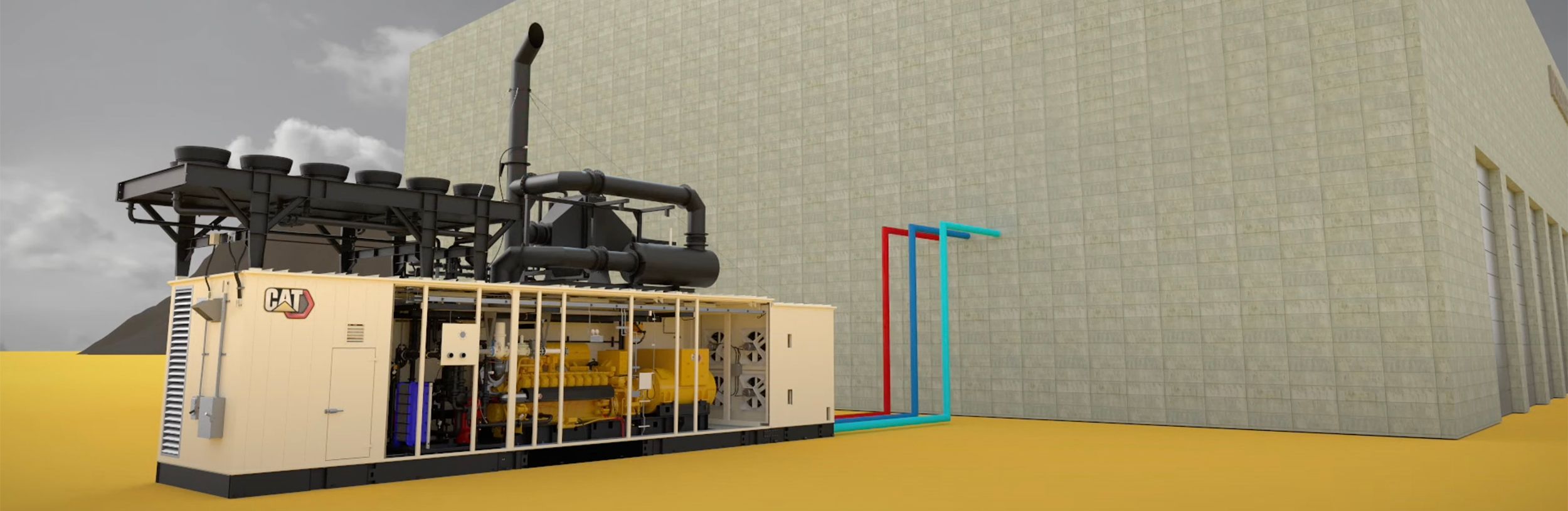

For locations where emissions regulations are less stringent, you may not need as much treatment. But I still recommend doing some cleaning to remove moisture, sulfur and siloxanes — it’ll save you headaches down the road. It’s also smart to talk to your engine provider about what their products can tolerate. Cat gensets for biogas applications, for example, are designed to handle higher levels of contamination in fuel.

Any other hurdles to consider?

Marty: Complexity, for sure. You’re dealing with unique fuels, complicated systems and sophisticated controls. That’s especially true in wastewater applications, where we’re often adding in cogeneration capabilities — producing electricity and heat — or natural gas blending.

That’s why I can’t overstate the importance of working with experienced people. You don’t want to be the guinea pig on someone’s first project. Choose suppliers and service providers who have a proven, documented track record with biogas. They know what can go wrong and can help you avoid mistakes that cost time and money.

What’s one thing people often overlook in biogas projects?

Marty: How critical it is to have local support. A biogas project requires significant upfront investment. To get the most return on that investment, your power plant must be up and running as much as possible. Without reliable access to parts and technicians, what happens when there’s a maintenance issue or failure? Problems that should take a day to fix could take a week or more. At that point, you're losing valuable resources and potential revenue.

Before choosing an equipment solution, be sure to ask any provider you’re considering these questions:

- How long have you been serving my area?

- Do you offer local service availability?

- How many service technicians do you have?

- Where are those technicians located?

You’ve been involved in dozens of biogas projects. What are your top tips for those looking to get started?

Marty: Every project is different, but you can’t go wrong with these four steps:

- Know your gas. Bring in a professional to measure how much biogas you’re producing and test its quality. That’s your baseline. This information can tell you if your project is feasible and how much cleanup is required.

- Understand your regulatory climate. What are the local air and safety requirements? What permits do you need? You can perform this due diligence in house or you can hire a consulting engineer to handle it — just don’t put it off. These issues can knock a project off track if you’re not prepared.

- Run the numbers. Figure out how much electricity you can generate with biogas and how much money that could save you over time. Then you can weigh the long-term financial benefits against the upfront costs.

- Choose your suppliers wisely. As I said before, experience is everything. From selecting equipment to installing the power plant to ongoing maintenance, work with people you can trust. That’s the best way to reduce risk and increase your likelihood of success.

Big thanks to Marty for sharing his expertise. Are you considering a biogas project on your site? Have more questions about the process and equipment involved? Ask our team of experts. We’re here to help.

Source: https://www.utilitydive.com/news/rng-industry-data-report-2024-american-biogas-council/740335/

Martin Hopkins

Market Development Manager for Biogas, Natural Gas & Cogeneration

Peterson Power Systems, Inc.

Contributor

With over 25 years in the power generation and utility industries, Marty has delivered substantial projects all over North America; his experience includes a wide variety of projects that involve mechanical, electrical and cogeneration. He has delivered more than 55 megawatts of biogas power in a variety of digester and landfill applications.

Related Stories

-

Beyond The Grid: Securing Power For Remote Projects

From mining to oil and gas to infrastructure development, every remote project relies on one essential factor: power. It gets the site up and running — and keeps it that way. Without it, equipment sits idle and progress halts.

Learn More -

Data Centers: Growing Pains?

The data-driven society we live in, from streaming devices and smart appliances to AI processing, continues to move demand for data centers in just one direction: up.

Learn More -

Funding The Electricity Gap

In March 2024, Mark Christie, commissioner of the Federal Energy Regulatory Commission (FERC), issued a dire warning about grid reliability. Here’s what he had to say about the rapid retirement of coal-fired power plants — and the much slower pace of bringing alternatives online:

Learn More -

Five Times It Pays to “Try Before You Buy” with Rental Power

Does the phrase “rental power” conjure up visions of electrical outages, severe weather events or unexpected breakdowns? A lot of organizations view rental primarily as an emergency solution, and for good reason. Immediate availability allows you to fill gaps and keep critical operations running with minimal or no interruption.

Learn More -

How Municipal Utilities Can Address Surging Power Demand

For many municipal utility managers I talk to, it’s getting tougher to continue providing the highest levels of reliability, service, and value. Customer preferences are changing. Some want 100% renewable power overnight; others simply care about cost. Other challenges are mounting, too: New technologies. Increased regulation. Workforce shortages. Budget constraints. And perhaps biggest of all, rising demand.

Learn More -

Act Now to Leverage CHP Tax Credits Up to 50%

The Inflation Reduction Act (IRA), signed into law in August 2022, provides nearly $400 billion in tax credits and incentives over a decade to promote climate change mitigation and stimulate clean energy development in the U.S. It’s the largest single investment in climate and energy in American history — and it includes the highest incentives ever provided by the federal government for combined heat and power (CHP) projects.

Learn More -

5 Steps to Sign-Off on a New Energy Solution

You’re a large energy consumer, maybe in healthcare, education, distribution or transportation. You’re facing pressure — internal, external or both — to increase your energy resiliency, lower your carbon emissions, reduce your energy costs, add capacity for expansion, or some combination of all four. You know you need to act (and soon), but you’re struggling with how to get started implementing a solution.

Learn More -

Is Your Organization a Good Fit for EaaS? And Is Your EaaS Partner a Good Fit for You?

Our EaaS team at Caterpillar has implemented solutions for all types of operations: from K-12 schools and grocery stores to industrial facilities. The concept — you purchase energy outcomes and turn ownership and upkeep of energy assets over to a third party — works for many organizations. How do you know if yours is one of them?

Learn More -

Demystifying the EaaS Model: Don’t Buy Power Products. Buy Energy Outcomes.

Software as a Service, or SaaS. Today, most applications — everything from Microsoft Office to Google Drive to Salesforce — are hosted by a third-party provider and made available via the web or a mobile app. You don’t need to install or configure anything on your computer, and the SaaS provider handles all maintenance, upgrades, and licensing. It’s more convenient for users and more affordable for businesses.

Learn More -

Hydrogen’s True Colors: A Key to Defining Carbon Intensity

Often referred to as a “clean-burning” fuel, hydrogen is the most abundant chemical substance in the universe because its combustion generates near-zero greenhouse gas emissions at the tailpipe. . It’s also colorless, odorless and burns with a near-invisible flame. So why does nearly every Google search or news story about hydrogen turn up terms like “green,” “blue” and even “pink”?

Learn More -

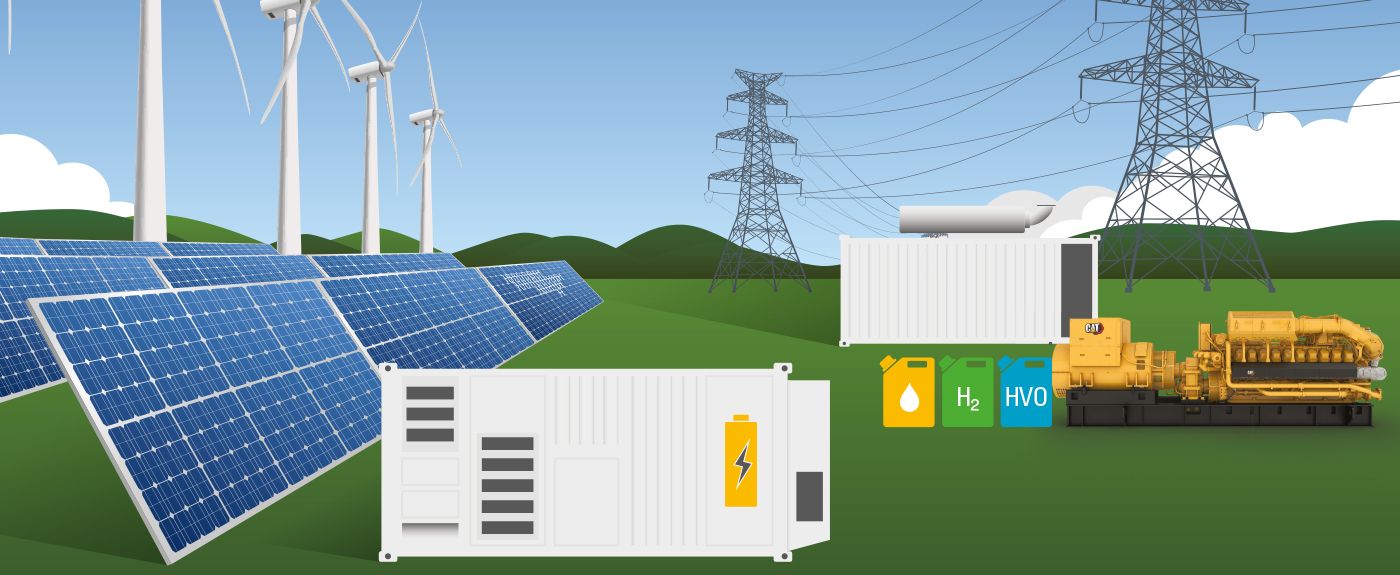

Distributed Energy Benefits and Grid Systems Integration

Our electric power system faces many challenges, and as the energy landscape evolves to address increased electrification, we will have even greater demand than ever before. Caterpillar is positioned to serve as a trusted partner with the technologies and expertise to provide alternatives to established energy sources and fuels that are reliable and cost effective.

Learn More -

Trends in the Energy Transition

When it comes to the ongoing efforts to decarbonize and reduce greenhouse gas (GHG) emissions, renewables are making up more and more of our sources of power generation, and we think this will continue—for many positive reasons. We have a lot of customers who are setting targets for Environmental, Social, and Governance (ESG) goals, aiming for improved carbon reduction.

Learn More