If you already have an existing account with another Cat App, you can use the same account to sign in here

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

Uptime All the Time

Mustang® Cat’s engine exchange program and rebuild capabilities keep gas compression operations up and running.

Parts & Services

Sustainability

About

Downtime is not an option for gas compression sites. When engines require a major overhaul or technology conversion, operators depend on quick turnarounds for this essential equipment. Through a vast dealer network, operators have immediate access to skilled technicians to address issues that may arise — from unexpected emergencies to routine maintenance and upgrades.

Cat® dealer Mustang® Cat created an innovative approach to reduce downtime when overhaul or significant maintenance work is required. By leveraging a robust gas engine exchange program and local technical support, gas compression operators can seamlessly replace an existing asset with the dealer’s in-kind swing engine within days to minimize operational disruption.

Additionally, operators have access to the dealer’s engine rebuild centers and comprehensive technical support capabilities to help ensure greater uptime and peace of mind.

Meeting Gas Compression Demands Wherever They Arise

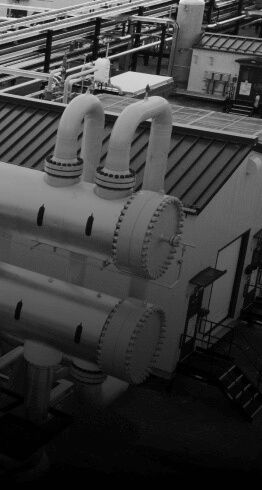

Serving the Southeast Texas region since 1952 — and the gas compression industry for more than 40 years — Mustang Cat offers one of the largest “swing engine” fleets for Cat G3600 engines, helping resolve unplanned downtime or downtime for scheduled maintenance by accessing a fleet of 80 standby rebuilt engines dedicated to gas compression.

Additionally, operators are supported by nearly 150 Mustang Cat oil and gas technicians located across multiple technical centers with the capability to rebuild large horsepower engines, totaling around 450 oil and gas engines a year, with the largest center in Houston capable of rebuilding an average of more than 200. The dealer has overhauled more than 1,200 G3500 and G3600 units since 2017.

Advantages of Swing Engine Backup Availability

Boasting more than 100,000 available horsepower at any given time, the engine exchange program provides ready access to a fleet of modernized G3600 solutions. Mustang Cat retrofits the standby engines with the latest Cat technology, such as the A3 and A4 Gen 2 kits, and CCV system to help lower greenhouse gas (GHG) engine emissions and improve performance.

Operators seeking to swap a G3600 engine can simply exchange a “dirty” core for a zero-hour, overhauled engine. Replacement downtime is limited to three to five days compared to the average four to six weeks needed to overhaul a unit. The ability to secure an engine on demand, while also having the option to increase horsepower and lower emissions with the Gen 2 kit, keeps operations running smoothly.

Through the engine exchange program, G3600 engines are ready to ship within 48 hours. As an overhauled engine leaves the facility, Mustang Cat receives another spare core to rebuild using Cat Reman components. This continuous replenishment cycle keeps inventory on hand for the next operator in need.

Continuous Rebuilding for Continuous Service

Rebuilds can be provided in large numbers in short order with the swing engine program. To support a leading gas compression services provider in rebuilding a portion of its high-horsepower fleet for optimized efficiency and reliability, Mustang Cat turned around four overhauled engines per week at its large engine rebuilt facility without missing a ship date for the entire 12- to 16-month duration. The Cat dealer’s technicians provided efficient service and delivery, helping the operator maintain more than 99% mechanical availability.

A key factor in achieving this uninterrupted level of uptime is ongoing support through the Cat dealer network. Cat dealers support each other with one goal in mind — provide the best solutions that help operators avoid costly shutdowns.

"At Mustang Cat, we are actively working to provide upgrade value upfront for operators,” said Madison Sims, General Manager, Power Product Support Sales for Mustang Cat. “Caterpillar designs its parts to operate as a complete system. Between genuine Cat parts, the dealer network and parts and services available throughout the lifetime of an engine, our customers are backed by the power of Caterpillar as a whole.”

First to Market with the Latest Technology

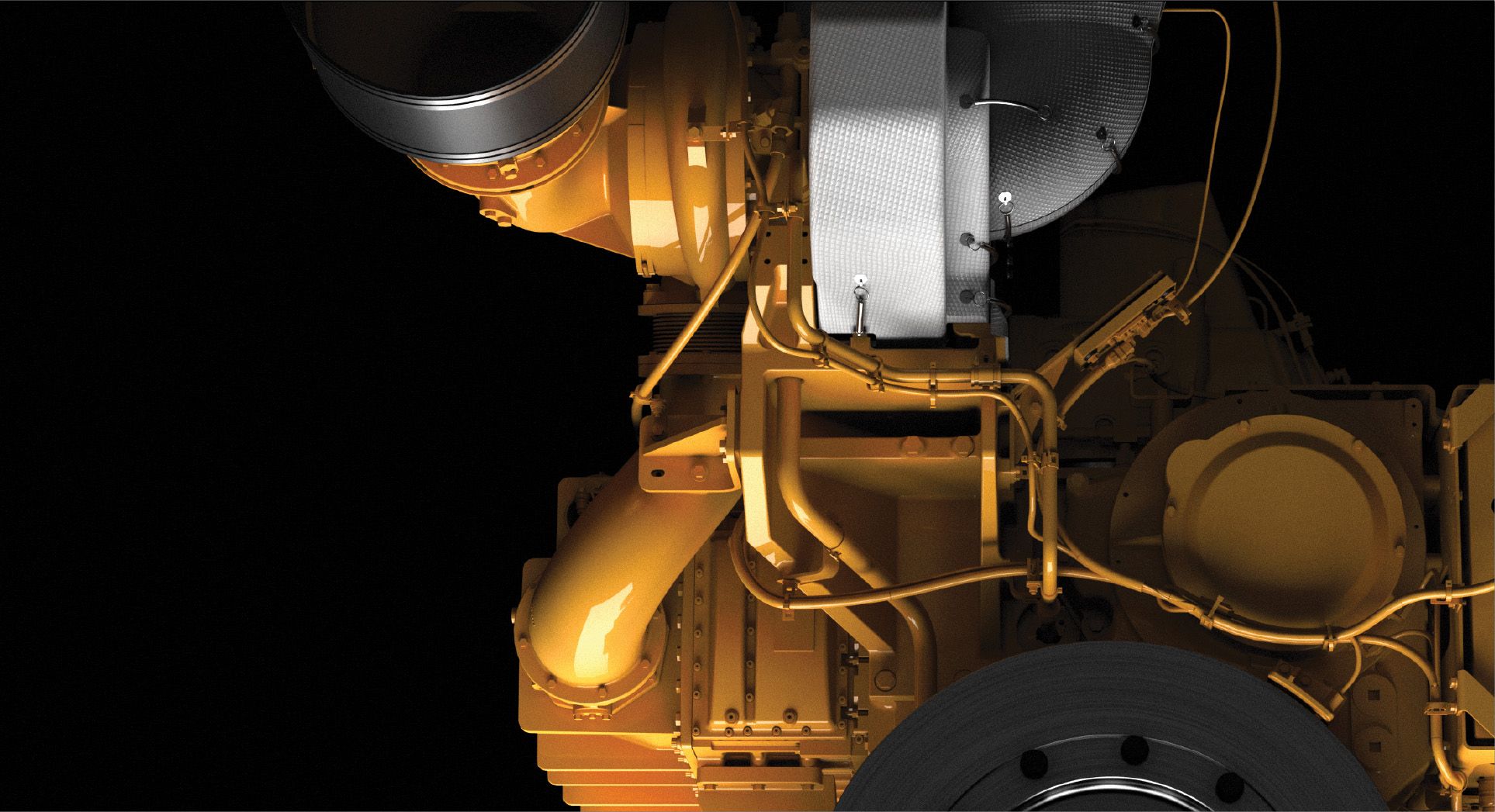

The G3600 engine is built for longevity and dependable performance, evolving with the release of Gen 2 kits that are available for the more than 8,500 active Gen 1 engines in the field.

“As an early adopter of the latest Caterpillar technologies, Mustang Cat is excited about the G3600 Gen 2 kit to further optimize lean-burn engine horsepower as well as decrease GHG emissions,” added Sims. “We’ve invested millions of dollars into our engine exchange fleet, with the goal of providing decreased downtime and supporting operators’ climate-related goals by being one of the first to market with the Gen 2 kit offering. Ultimately, we're helping to maintain or decrease total cost of ownership for operators in the long run. Their success is our success.”

As gas compression operators face intense uptime requirements, close dealer relationships as well as innovative approaches can help ensure companies are empowered to meet their commitments.