Increasing demand for LNG, especially from emerging economies in Asia, is expected to continue throughout the decade,6 and producers will need to meet that demand with increased supply. Additionally, a 2024 report from Wood Mackenzie forecasts growing demand during the 2020s, which remains stable through “most of the 2040s.”7

As LNG continues to drive increasing demand for natural gas production and transportation, gas compression operators have an opportunity to support efforts to meet that demand. Advanced technology plays a vital role in the industry’s gathering and processing infrastructure, and Caterpillar Oil & Gas is positioned to empower gas compression operators with innovative solutions that help reliably and cost-effectively expand production while also supporting climate-related goals.

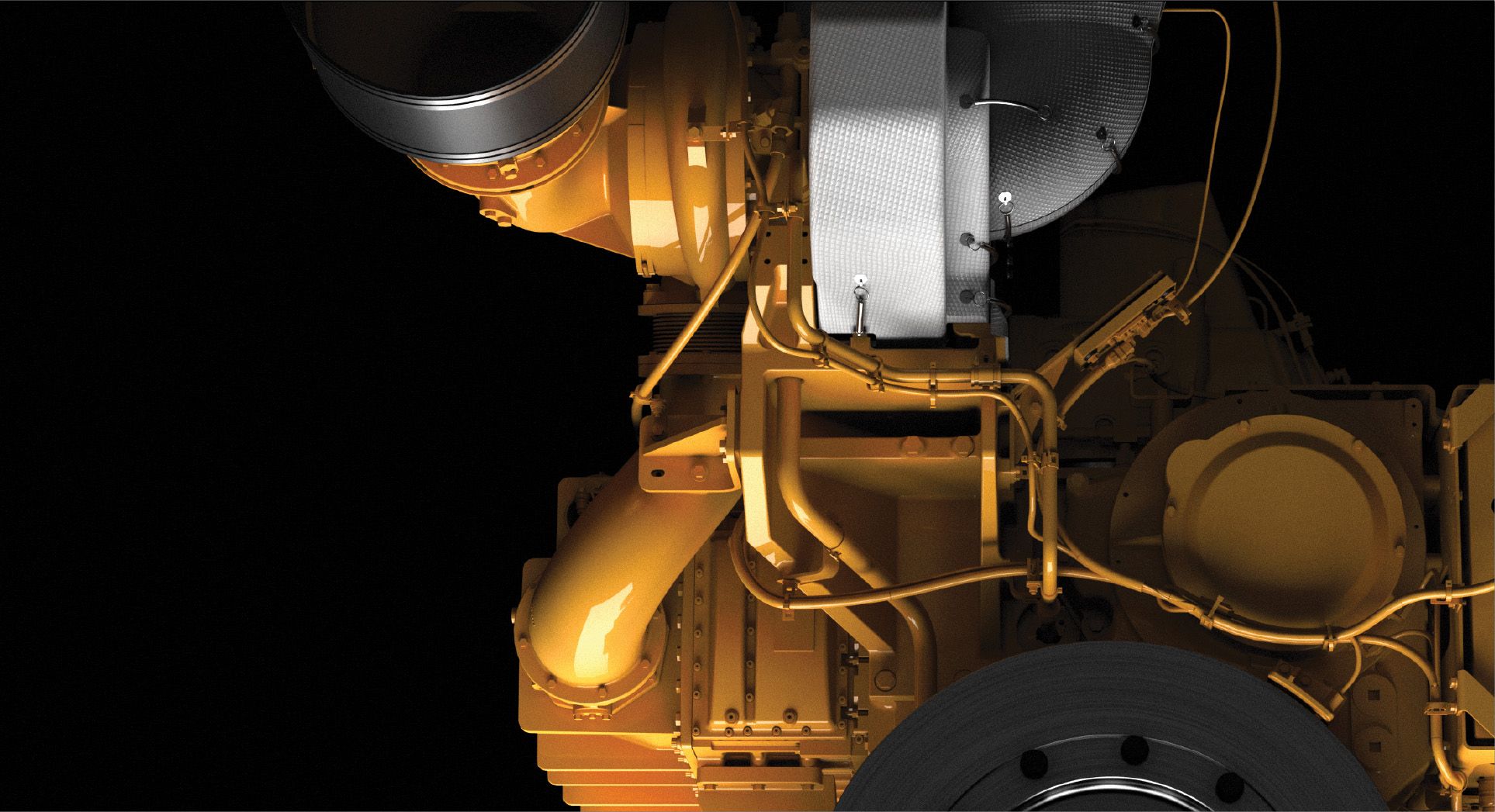

As one example, the field-proven Cat® G3600 A4 Gen 2 engine delivers reliable performance across a range of site conditions. A4 Gen 2 engines are available with multiple cost-effective options to meet specific needs and operating conditions. From lowering methane emissions to providing greater power density with an optional 10% power increase, the Gen 2 enables operators to move more gas at a lower cost while supporting climate-related objectives, compared to the Gen 1.

Based on specific testing conditions,8 the A4 Gen 2 achieves the following emissions reductions compared to the Gen 1:

- Up to 33% methane reduction.

- Up to 32% volatile organic compounds (VOCs) reduction.

- Up to 24% formaldehyde reduction.

- Up to 13% carbon monoxide reduction.

- Up to 5% greenhouse gas (GHG) reduction.

The operational dependability as well as fuel flexibility the G3600 A4 Gen 2 engine provides are just a few of the reasons why this technology powers many gas compression sites across a variety of operating conditions. Regardless of an engine’s age, there are convenient options available for parts, maintenance and service.

Powering Performance with Data

Uptime is crucial for all gas compression operations, including those focused on supplying LNG. Any disruption could lead to unexpected downtime, potentially impacting gas supply. Utilizing reliable, field-proven technology together with knowledgeable, skilled support remains essential to help mitigate any challenges encountered in the field.

A gas compression operator in the Marcellus Shale understands firsthand how important dependable technology and service are to their operations. In addition to reliable uptime, this operator works closely with their Cat dealer, who provides 24/7 operational support with remote engine monitoring and strategically planned engine maintenance. As a result, overhaul timeframes were extended by 15% to 20%, not only lowering the operator’s total cost of ownership (TCO), but also supporting cost-effective gas production – a desirable outcome for any supplier.9

A Key to Unlocking the Energy Future

As LNG demand continues to grow, gas compression operators can leverage innovative solutions to help capture future opportunities and support the world’s energy needs. Caterpillar engines help facilitate LNG production at this critical time and provide a range of benefits. Adopting advanced technology that keeps pace with the dynamics of the industry is key to improving efficiency, maximizing uptime and lowering emissions for long-term success.