If you already have an existing account with another Cat App, you can use the same account to sign in here

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

Hybrid Energy Technology Enablers Deliver

Efficiencies That Add Up

Advancements offering fuel flexibility and autonomous control are the latest tools to help reduce costs

Parts & Services

Sustainability

About

As fuel is always one of the greatest expenses in the oilfield, technological developments that drive greater efficiencies are top of mind for E&Ps and drillers. Newly available electrification and optimization technologies lower fuel consumption and related greenhouse gas (GHG) emissions while maintaining on-site reliability and durability.

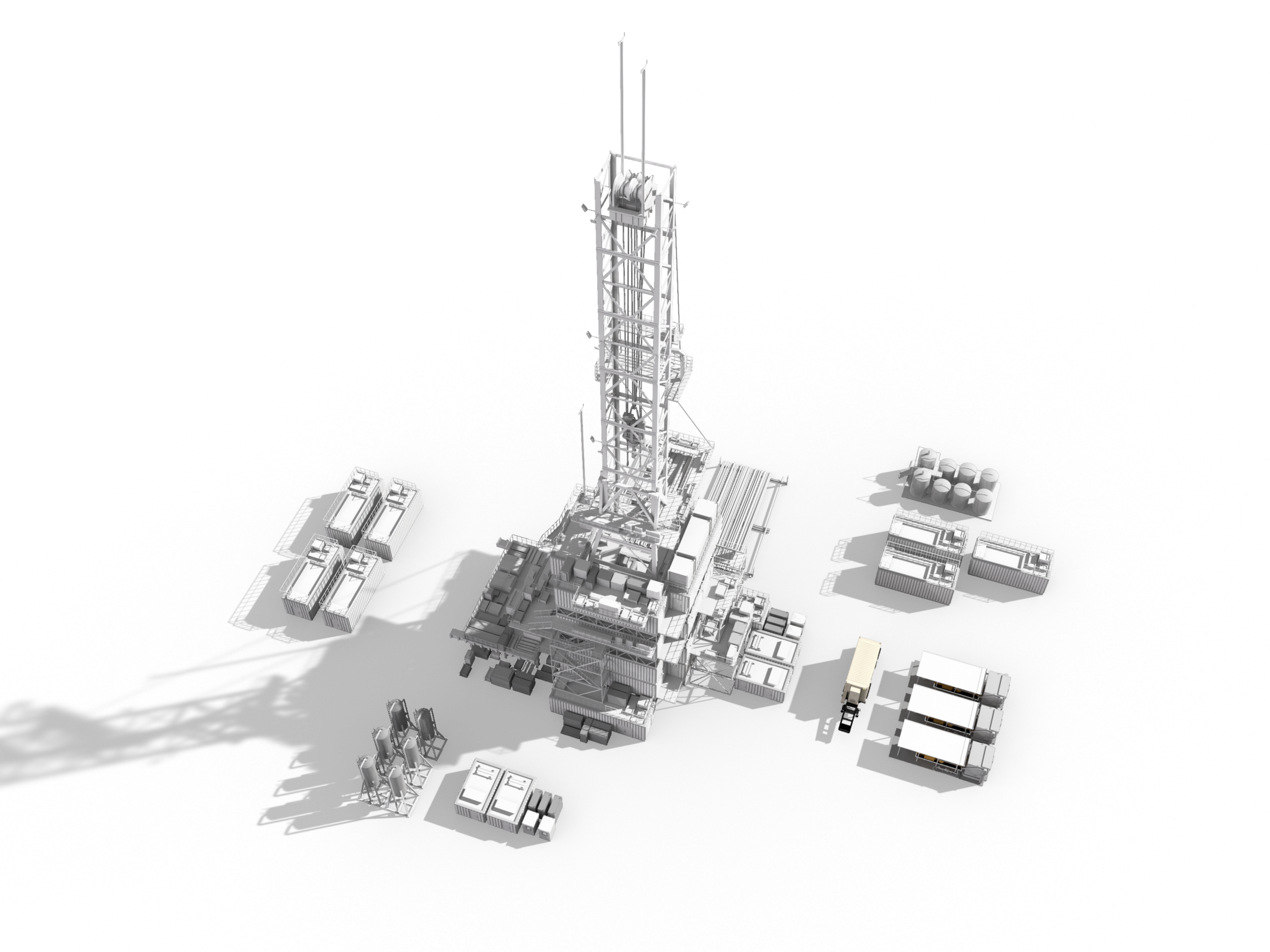

With a suite of hybrid energy technology enablers, Caterpillar Oil & Gas empowers oilfield companies to modernize and expand their power options at the wellsite. Used in combination with any battery of a driller’s choice, these solutions are purposefully designed to accommodate dynamic operating conditions and seamlessly integrate with multiple types of renewable energies. Enabling a company’s selected battery to discharge stored power when needed is a vital function performed by the Cat® Bi-Directional Power Inverter. This component easily transitions between grid forming, firming and following modes for simple off-grid and on-grid operation. Cat site controllers effortlessly manage utility export and import requirements for integration with traditional generator controllers as well as renewable energy sources.

When combined with a gas genset supported by energy storage, these hybrid energy technologies enable faster transient response than with diesel-only rigs. Smart technologies easily configure into current rig setups, giving operators and drillers more flexibility when selecting fuel types. Additionally, deploying a hybrid energy package optimizes performance and cost savings by incorporating digital monitoring capabilities and system automation to effectively manage rig power demand, engine load and site efficiency.

Enabling Hybrid Energy Configurations

Digital technologies are transforming site efficiency, allowing for continuous fuel monitoring and management capabilities at safer distances through autonomous controls as well as less frequent touch points with equipment. In addition to improved safety, applying hybrid energy technologies brings significant cost savings to oilfield operations.

With the Cat Smart Engine Management System (EMS), greater operational benefits are unlocked. This powerful technology aligns performance with programmed targets and helps reduce maintenance costs by lowering the number of runtime hours engines accumulate. With Smart EMS, drillers can reduce engine runtime up to 25%, cut fuel consumption up to 10% and improve diesel displacement up to 15%, without sacrificing power, performance or productivity.1 Smart EMS also supplies a robust human-machine interface (HMI) that provides drillers easy, touchscreen access to see rig demand and engine load at a glance for trusted remote oversight. Cat EMCP 4.4 digital controls underpin this smart system to provide enhanced genset paralleling and remote communications capabilities.

Cat natural gas-burning gensets, such as the Cat Dynamic Gas Blending™ Gen 2 upgrade kit, are another crucial component of a hybrid-powered system. Specifically engineered to run on wellsite gas, these assets ensure an abundant supply of low-cost fuel. Companies can select the individual components that support their unique goals and project specifications for optimal benefits. This flexibility enables drillers to benefit from a complete, customized approach that provides proven reliability and durability.

Such wellsite optimization technologies work seamlessly together to provide drillers and operators more insight and flexibility than in years past. As operators seek to reduce costs and stay competitive, a hybrid energy technology suite offers significant benefits, including improved safety, enhanced performance and reduced GHG emissions.

1 Cat® Smart EMS. https://www.cat.com/en_US/by-industry/oil-and-gas/land-drilling-production/smart-ems.html

*Results based on field data. Actual performance may vary.

Related Content

-

Cat® Hybrid Energy Technology Enablers

Cat® Hybrid Energy Technology Enablers include hardware, digital systems and expert support to increase efficiencies and lower emissions.

Learn More -

Smart Engine Management System

Cat Smart Engine Management System efficiently manages the number of engines required to satisfy performance needs.

Learn More