If you already have an existing account with another Cat App, you can use the same account to sign in here

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

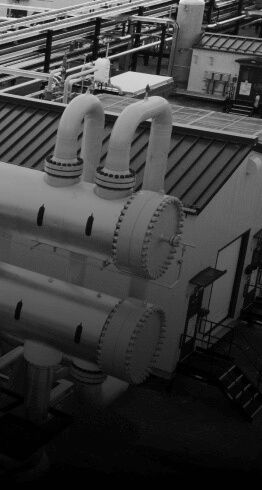

What’s Fueling the Evolution of

Gas Compression?

Gas compression engine technology has kept pace with the rapid advancement of exploration and production techniques thanks to a commitment to continuous innovation and engineering ingenuity. From the shale revolution to current data and energy expansion trends, Caterpillar Oil and Gas is positioning gas compression operators to meet evolving requirements and growing global energy needs by modernizing their engines to reduce greenhouse gas (GHG) emissions while maintaining performance.

As energy operators continue powering the world, demand for gas compression technology remains robust1. Natural gas will be essential to meeting global energy requirements and climate-related goals – today and in the future.

Shale 3.0: Natural Gasification at Lower Cost

The evolution of gas compression begins with innovations that spurred the success of North America’s shale gas production. Horizontal drilling and hydraulic fracturing revolutionized oil and gas operations, with first-generation Cat® engines powering operations in rugged conditions and at higher pressures.

The push into new frontiers led to significant demand for gas compression solutions and technologies that can adapt to changing conditions – and new regulations.

The industry is now in a “Shale 3.0” era in which operators must keep capital discipline top of mind2. There’s also continued pressure to meet increasing global energy demand while improving efficiency by adopting technologies that help lower GHG emissions.

Reliable Uptime with Greater Efficiencies

Given the strong demand for reciprocating engines3, manufacturers continue to support assets that are currently operating in the field. To underscore this point, nearly 10,000 Cat G3600 engines are in operation. That’s a testament to the system’s dependable power and longevity – and to the commitment to optimize operators’ return on investment.

Cat gas compression engines are not only field-proven to maximize uptime but also are built to be rebuilt. This enables operators to reduce the total cost of ownership through adding key upgrades during overhauls to increase power density and lower GHG emissions4.

Caterpillar Oil & Gas continuously strives to develop new technologies that improve performance while simultaneously supporting climate-related targets. The G3600 Gen 2 upgrade kit, bolt-on closed crankcase ventilation system and carbon capture solution demonstrate the important developments that enable gas compression operators to continue utilizing existing assets as the industry evolves.

Positioning Gas Compression Operations for Tomorrow’s Requirements Today

Global analysts project that the global gas compressor market will grow 3% to 4% CAGR over the next decade5, noting rising natural gas consumption and high demand for energy-efficient process gas compressors. As downtime isn’t an option and the need to move greater amounts of gas cost effectively is crucial, gas compression operators are proactively timing upgrade installations with planned overhauls to minimize nonproductive time. This trend supports companies’ compliance and operational requirements simultaneously.

The oil and gas industry has a history of adapting to shifting regulatory frameworks with innovative technological approaches. Such advances allow gas compression operators to leverage their substantial capital investments to realize a greater ROI while achieving climate-related targets and operational efficiency. This strategy is key for the industry to continue to supply the world’s energy safely, reliably and economically.

1. Gas Compression Magazine. September 2024. 2024 Forecast for Compression: Demand for Gas Compression Remains Strong. Accessed online 23 September 2024. https://gascompressionmagazine.com/issues/september-2024/#page_60

2. Caterpillar. The Energy Pipeline Podcast, Ep. 50: The Evolution of Gas Compression in Oil and Gas. June 2024. https://www.cat.com/en_US/campaigns/awareness/the-energy-pipeline/the-evolution-of-gas-compression-in-oil-and-gas.html

3. Gas Compression Magazine. September 2024. 2024 Forecast for Compression: Demand for Gas Compression Remains Strong. Accessed online 23 September 2024. https://gascompressionmagazine.com/issues/september-2024/#page_60

4. Caterpillar. Dependable Engine Performance Supports Natural Gas Compression Operation. https://www.cat.com/en_US/by-industry/oil-and-gas/case-studies/repsol-cleveland-brothers-g3600.html

5. Imarc Group. Gas Compressors Market Report by Compressor Type (Positive Displacement Compressor, Dynamic Compressor), End Use Industry (General Manufacturing, Construction, Oil and Gas, Mining, Chemicals and Petrochemicals, Power Generation, and Others), and Region 2024-2032. https://www.imarcgroup.com/gas-compressors-market#:~:text=The%20global%20gas%20compressors%20market,are%20fueling%20the%20market%20growth

Related Content

-

The Evolution of Gas Compression in Oil and Gas

In this episode of the Energy Pipeline Podcast, Rodney Harms, Senior Product Manager for Cat Oil and Gas, discusses the challenges and future of gas compression in the oil and gas industry. The industry is facing the challenge of meeting the growing global demand for natural gas while adapting to changing regulatory frameworks and addressing environmental concerns. The focus is on energy expansion and meeting the energy needs of the world in a sustainable way. Caterpillar Oil and Gas is working on solutions to reduce emissions and improve efficiency, including upgrades to existing assets and the development of new technologies.

Learn More -

A Multi-Pronged Strategy for Lowering Engine-Driven Gas Compressor Emissions

The natural gas sector is anticipated to continue growing over the next several years. However, gas compression operators face continued pressure to meet increasing global demand for energy while also lowering tailpipe greenhouse gas (GHG) emissions.

Learn More -

Gas Compression

Caterpillar has a solution to fill your needs for gas compression. From the broadest range available of gas engine power ratings, to a full complement of electric motors, there’s a Cat® driver to fit your application.

Learn More