If you already have an existing account with another Cat App, you can use the same account to sign in here

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

Electric or Gas: Weighing Your Gas Compression Options

Parts & Services

Sustainability

About

Interest in utilizing electric power in gas compression operations has steadily increased over the past decade due to the rise in greenhouse gas (GHG) emissions permitting requirements. Each option available to gas compression operators — electric motors, traditional gas engines and gas turbines — offer advantages. However, choosing the best system for a specific project is determined by site requirements and operators’ goals.

Electric Motors Simplify Expenses and Compliance

Electric motors are available in centrifugal and reciprocating configurations and produce zero GHG emissions on site, as they run on electricity. This is a compelling advantage in the world’s most highly regulated regions. Additionally, electric motors can reduce noise pollution given the reduced noise output compared to gas engines.

Electric motors also help lower capex and opex. Purchasing an electric motor typically costs less than a gas engine. Maintenance costs are also lower, requiring annual oil changes and occasional sensor and air filter replacement. The reduced maintenance requirements significantly reduce downtime.

The simplistic design also streamlines installation and packaging. Electric motors’ smaller overall footprint eases logistics and setup.

Rural gas compression sites may not be suitable for operating electric motors, however, as this primary mover requires on-site access to high-power electric lines. Electric motors can also incur additional costs such as purchasing right-of-way as well as power lines, poles and other infrastructure. Variable speed control functionality is an additional expense as well, and the price of electricity is typically greater than using natural gas.

Gas Engines and Gas Turbines Offer Field-Proven Durability, Long-Term Cost Savings

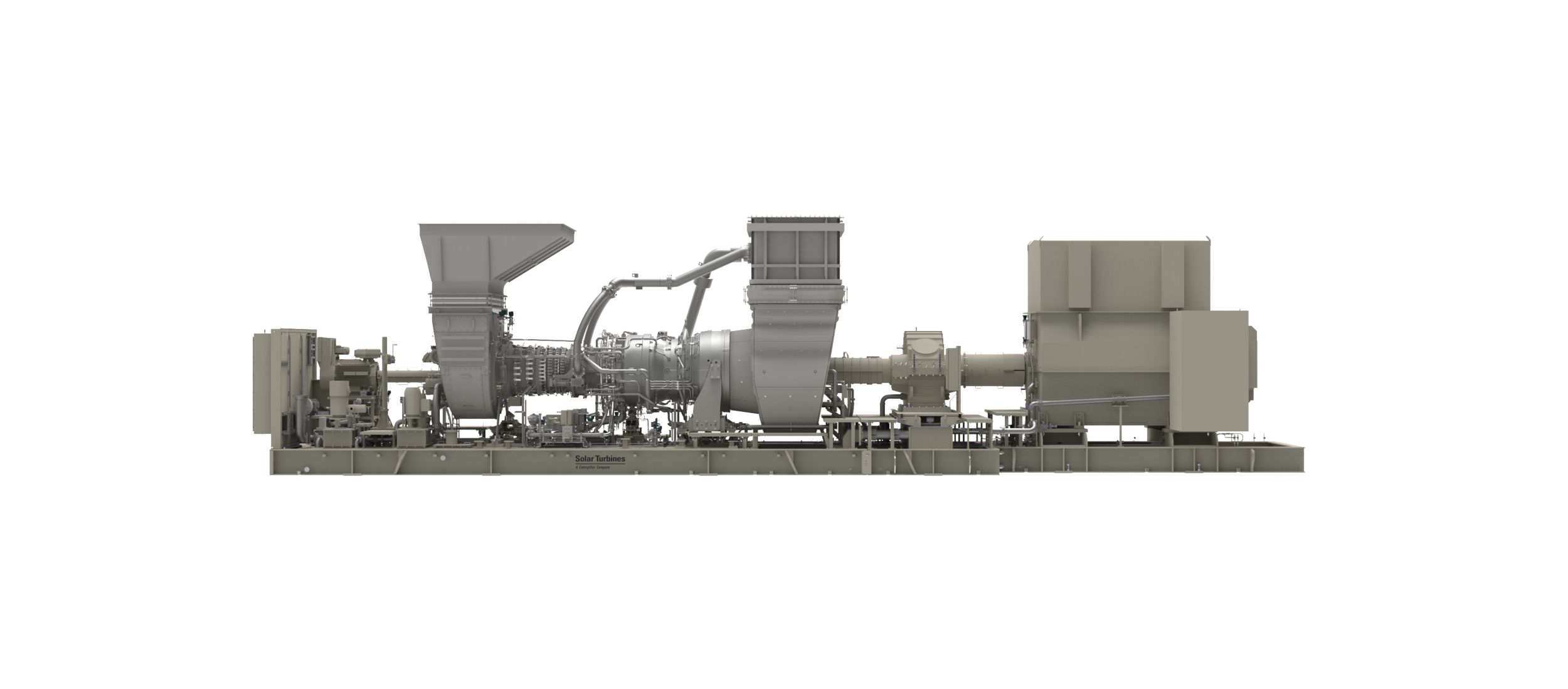

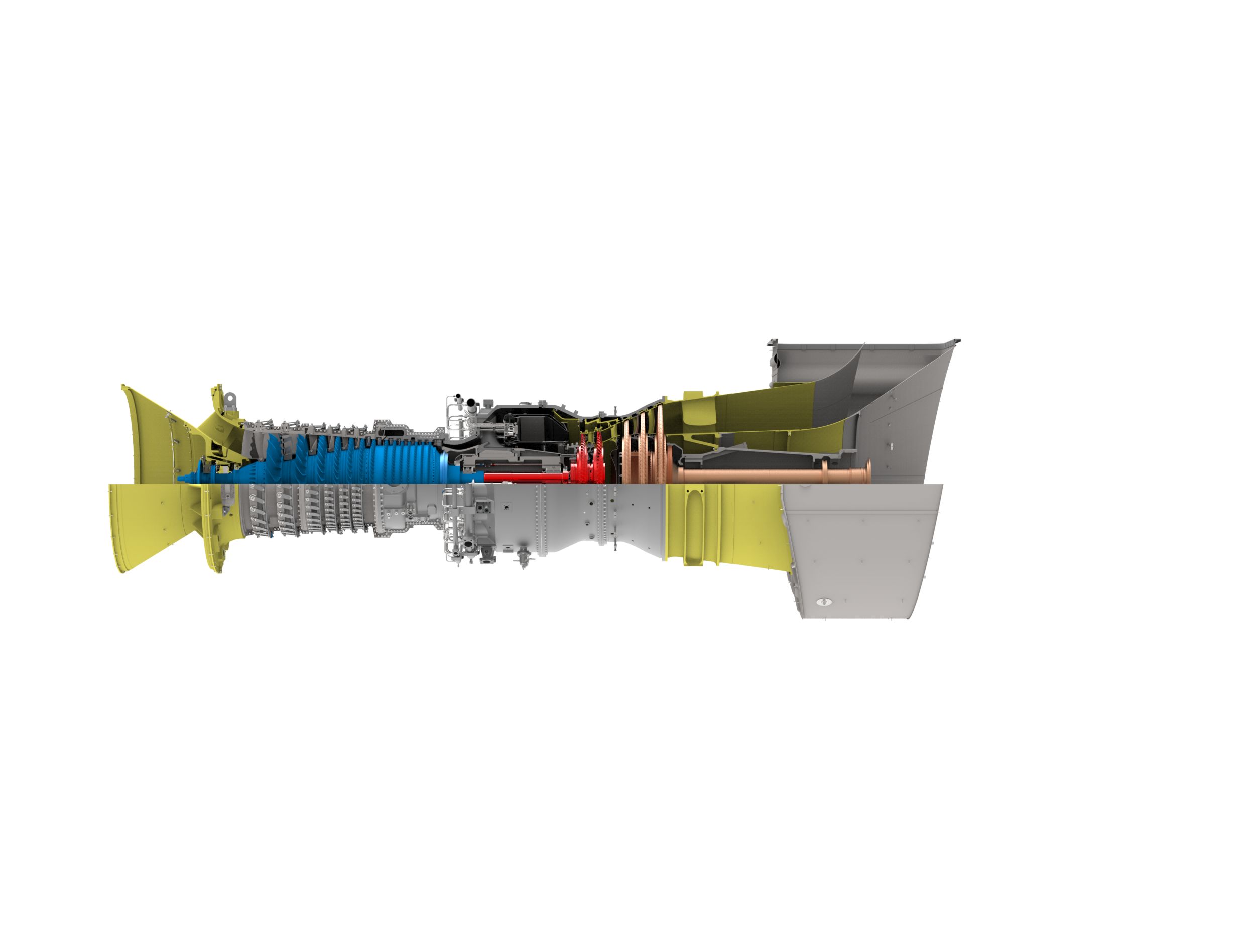

Gas engines and gas turbines, like those manufactured by Caterpillar subsidiary Solar Turbines, offer gas compression operators a reliable solution for specific applications in addition to maximum flexibility as these power options can be operated in any location, no matter how remote. Downtime isn’t an option, and both gas engines and gas turbines are widely known for delivering consistent and dependable power. This enables them to be more impervious to grid fluctuations and minor weather events.

The required fuel source is inherently available, as the natural gas that’s compressed is burned to generate power. This eliminates the need to tap into the electric grid or build its associated infrastructure.

With gas engines, controlling gas flow is simple. It’s easy and straightforward to slow engine speed to reduce gas flow when a portion of a site’s assets are offline for maintenance as variable speed control is built in. While the initial capital expense for a gas engine may be greater compared to an electric motor, Cat® gas engines are built to be rebuilt and can operate for decades. This ultimately leads to lower total cost of ownership and operating costs.

Gas turbines may help lower NOx, and potentially methane, emissions depending on load cycle. Additionally, gas turbines operate most efficiently within a specific pressure range, which can provide a smart, economical choice for processing and booster stations where a significant amount of gas — as much as hundreds of millions of cubic feet a day — moves through pipelines with minimal pressure drops. Given this operating specification, gas turbines may be less effective at the wellhead or for gas lift or gas gathering. In applications where gas pressures can start as low as zero to 50 psi in unconventional wells and must be raised to an average pipeline pressure of 1,200 psi, electric motors and gas engines tend to be the more efficient choice.

Familiar gas engine and gas turbine designs also support maintenance practices. With expert technicians available worldwide through the Cat dealer network, overhauls and routine maintenance protocols can be reliably performed on schedule to maximize an operator’s investment.

Determining if an electric motor, gas engine or gas turbine is best for a specific application depends on several factors — emissions, costs, maintenance and availability of electricity. Regardless of the solution, Caterpillar Oil & Gas offers expert engineering and technician support. The Cat dealer network is also available to help select the right power source for every gas compression operation.