If you already have an existing account with another Cat App, you can use the same account to sign in here

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

Cat® Reman Brings New Life To BDZ’s 336 Excavators

When your trusted excavator starts costing more than you want to pay in repairs, buying new may seem like the only option. But what if you could return it to like-new performance for a fraction of the price? Here’s how Cat® dealer N C Machinery made it happen for BDZ Construction, using Cat Reman components to keep rebuild costs and downtime low.

Estimated read time: 4 minutes

“Being able to use Cat Reman parts on the rebuild gave us a good cost savings. And we know from past experiences that Cat Reman parts have held up.”

— Colin Graham, Equipment Manager, BDZ Construction

A Surprising Suggestion: Rebuild, Don’t Replace

Based in Bothell, Washington, BDZ Construction specializes in site development and underground utility work — relying on Cat® construction equipment to keep projects running smoothly and efficiently. When BDZ’s 336 excavators began nearing end of life after years of hard work, the company faced a tough decision: buy new or explore other options.

“Everybody in the company really liked these 336s,” says Colin Graham, BDZ’s equipment manager. “But they were at the life point where they were starting to become unreliable.”

That’s when the team at Cat dealer N C Machinery raised the idea of rebuilding the machines for a second life. This was something BDZ, like most excavator owners, hadn’t considered before. After all, many companies typically don’t find it economical to rebuild an excavator.

Greg McClelland, product support sales manager at N C Machinery, explains, “It’s an alternative that a lot of businesses don’t even think about.” But with the available Cat parts, services and repair options, “rebuilding excavators is a great, cost-effective option.”

To prove the value, McClelland and his team ran various scenarios to compare the total cost of ownership for rebuilding versus other alternatives. The results spoke for themselves.

“The savings that they would get off of doing these three machines would allow them to purchase and grow their fleet by one more machine,” says Joe Hainer, product support sales representative at N C Machinery.

Cutting Costs Without Cutting Corners

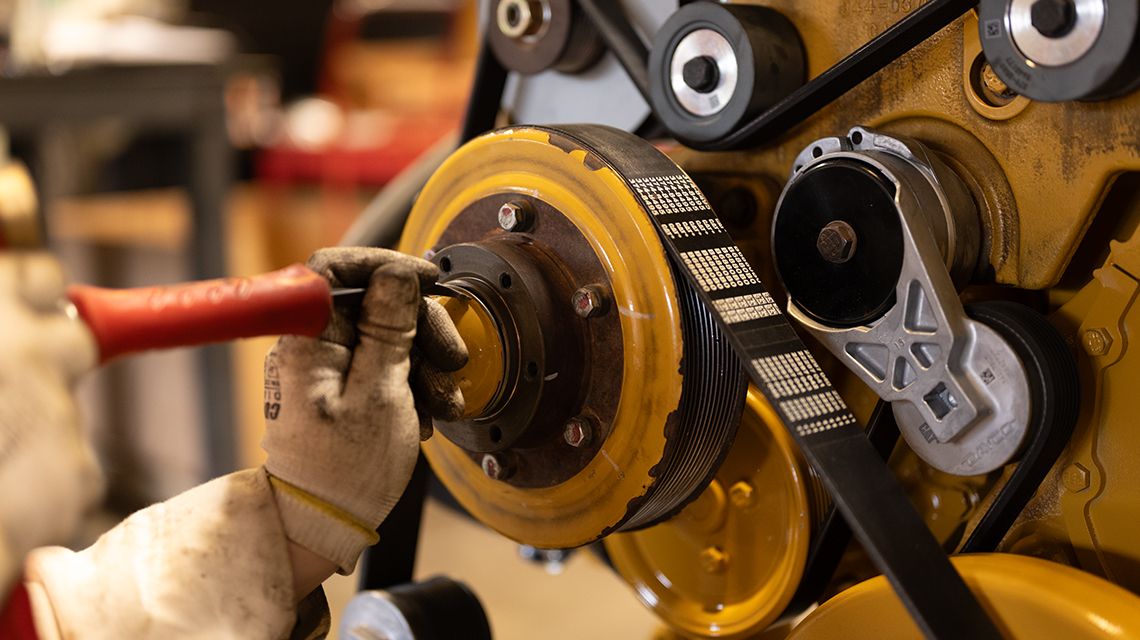

As part of their rebuild plan, N C Machinery emphasized that the use of Cat Reman products would help control costs and limit downtime. As with other machine rebuilds, these remanufactured parts support the financial savings needed to make these 336 rebuilds worthwhile.

Available for a fraction-of-new price with core return, Cat Reman parts are drop-in ready solutions that can be installed quickly — saving time and labor when compared to rebuilding major components. And they didn’t require BDZ to sacrifice quality or performance.

“It’s like-new quality,” says Brydon McMillan, a service technician at N C Machinery who worked on the 336 powertrain and hydraulics rebuilds. “Cat Reman follows reusability guidelines and makes sure that their parts meet like-new specifications.”

To rebuild BDZ’s 336 excavators, N C Machinery replaced the original engines, hydraulic pumps and motors with Cat Reman components. Like all Cat Reman products, they were remanufactured to original Caterpillar performance specifications and tested to meet the same standards as new Cat parts. They also incorporated the critical engineering updates and came with a same-as-new, 12-month Caterpillar Limited Warranty.1

“Cat Reman helps cut the cost for the customer and helps us maintain our timeline.2”

— Joe Hainer, Product Support Sales Representative, N C Machinery

Eight Weeks To Like-New Quality

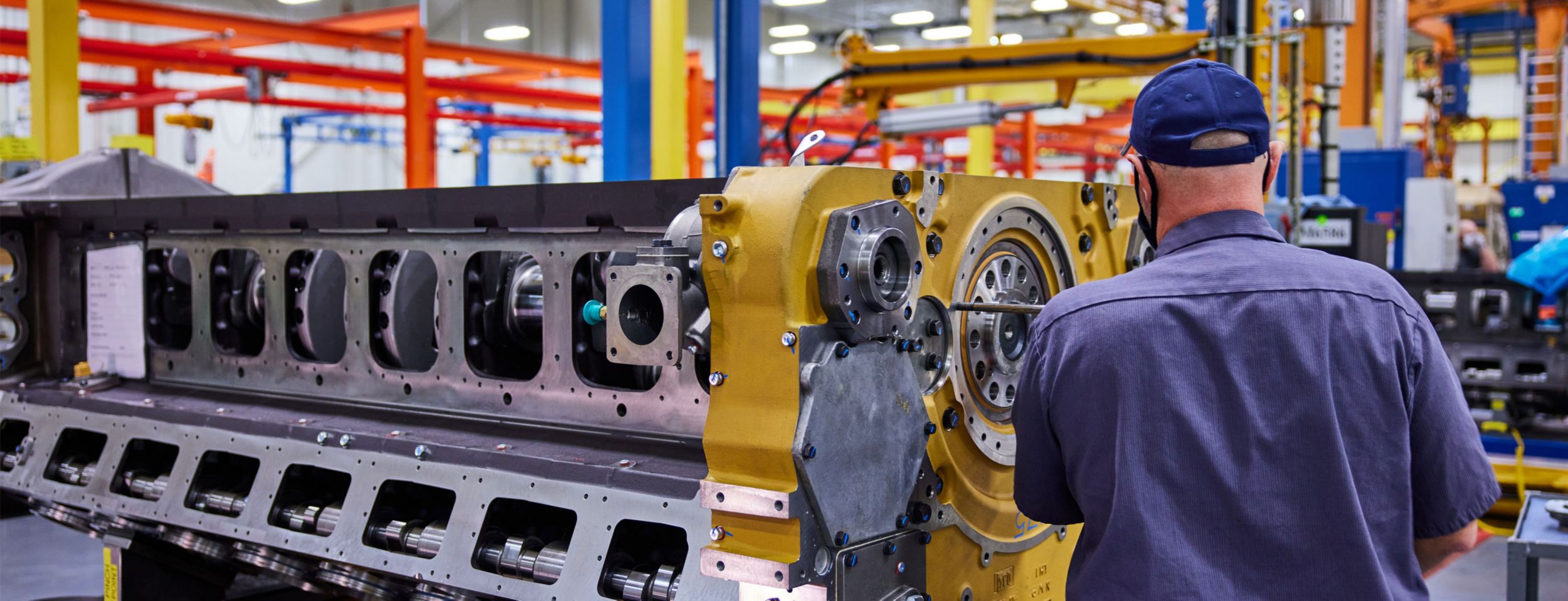

Each of BDZ’s excavators went through a Cat Certified Powertrain + Hydraulics Rebuild, a robust restoration process that covered everything from the machine’s engine all the way back to its axle.

N C Machinery fully disassembled each machine and inspected all the components — including the cab, engine, control valve, swing drive and final drives. Components that weren’t replaced with Cat Reman products were either rebuilt or replaced with genuine new Cat parts. Then, the excavators were reassembled and tested to make sure they performed like new.

Using Cat Reman parts wherever possible enabled a quick turnaround on each rebuild. This allowed BDZ to keep their operations running smoothly, understanding that the excavators would be off the jobsite for a shorter period than other options would have allowed.

For BDZ’s first 336 rebuild, “We did it in eight weeks from start to finish and had it right back to them on time,” Hainer says. “Cat Reman parts help us hold our timeline and the customer is able to get the machine back up and running.”

“They perform like new, uphold the reusability guidelines that Caterpillar puts out and make a quality product that customers can depend on.”

— Joe Hainer, Product Support Sales Representative, N C Machinery

The Rebuild Payoff: Extended Life, Lower Costs

Historically, “the mantra was, it's not economical or feasible to rebuild an excavator,” says McClelland. “But we did a presentation for them about the certified rebuild program and what expectations are, what's required. And that really piqued their interests.”

“We’ve been dealing with N C Machinery probably the full time that BDZ has been in business, so just over 30 years now,” says Brandon Jensen, BDZ’s owner and president. “They strive to support us, and we feel that they are the best out there for parts and service and support.”

When the first rebuilt 336 returned to work, the BDZ team immediately noticed improvements in both hydraulic response and power. Confident that the process helped restore performance while keeping operating costs and downtime low, they soon embarked on rebuilds for their two other end-of-life excavators.

“Everybody was really happy with how it turned out,” Graham says. “I don't think that there’s a lot of people out there that realize how cost-effectively you can rebuild an excavator.”

Are you ready to see how Cat Reman components can help you save money on an excavator rebuild? Reach out to your local Cat dealer today to discover how a Cat Certified Powertrain + Hydraulics Rebuild can give your equipment a second life — for a lower price than new equipment.

1Warranty can vary by model and application; limitations apply. For complete details about the applicable Caterpillar Limited Warranty, contact an authorized Cat dealer.

2Any Cat Reman cost savings statements are based on return of core; core conditions apply.

Cat Reman

The thought leaders and subject matter experts involved in the design, development, distribution and marketing of Caterpillar’s remanufactured, like-new products.

Related Blogs

-

The Secret Sauce of Cat® Reman

Want to know what makes Cat® Reman parts unlike other products on the market? Join members of the Caterpillar team as they detail the ingredients — the affordability, availability and sustainability benefits — that make up the secret sauce of Cat Reman.

SEE WHAT IT’S MADE OF -

4 On-Highway Truck Engine Tips to Save You Fuel and Money

Turn to these truck engine tips to keep your hauler running longer, with one step that could cut cost per hour by 80%.

Learn More -

This Shop Gets Trucks (and Bees) Back on The Road Fast

See how I-70 Truck Center works with Caterpillar to get rigs — including semis hauling honeybees — back on the road fast.

Learn More -

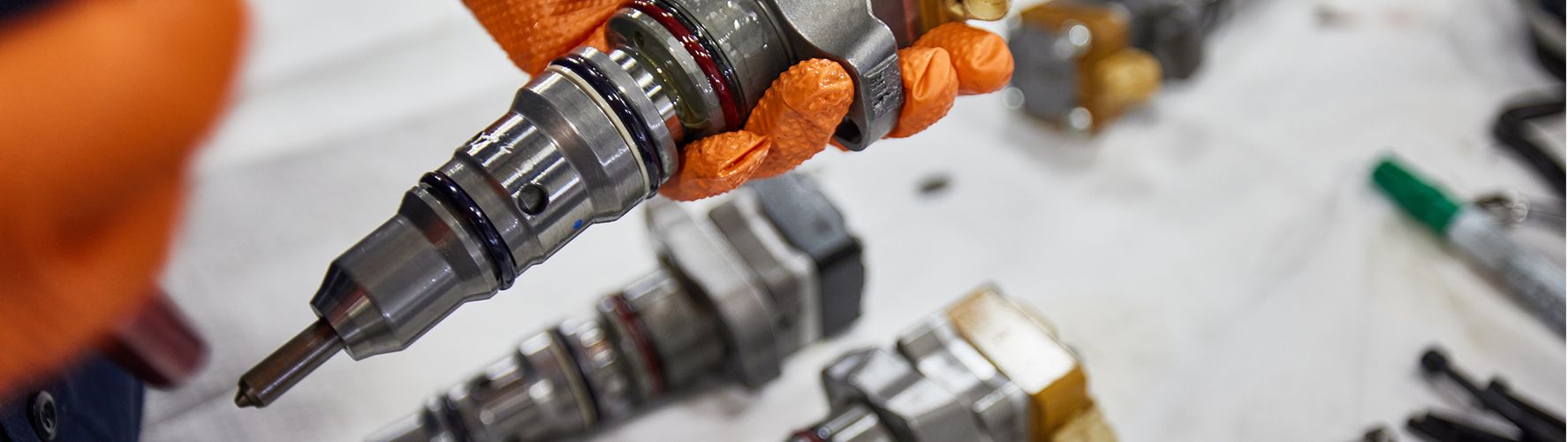

3 Ways to Save with Cat Reman Injectors

Wonder what Cat® Reman injectors can offer your equipment? Explore these three ways that remanufactured injectors from Caterpillar can save you on expenses while optimizing your engine. Get efficiency with proven availability, protection and long-lasting quality.

READ THE ARTICLE