If you already have an existing account with another Cat App, you can use the same account to sign in here

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

How to Remove and Install Cat® J Series Bucket Tips

Estimated read time: 3 minutes

Cat® J Series tips for excavator and wheel loader buckets come in a range of shapes and sizes, designed to fit your specific needs. If you're looking to get the most out of your machine, it's important to know what options are available and how to install and remove these tips properly.

See the video for more about Cat J Series tips, and then continue reading for the steps for replacing the tips.

Cat J Series Tip Options

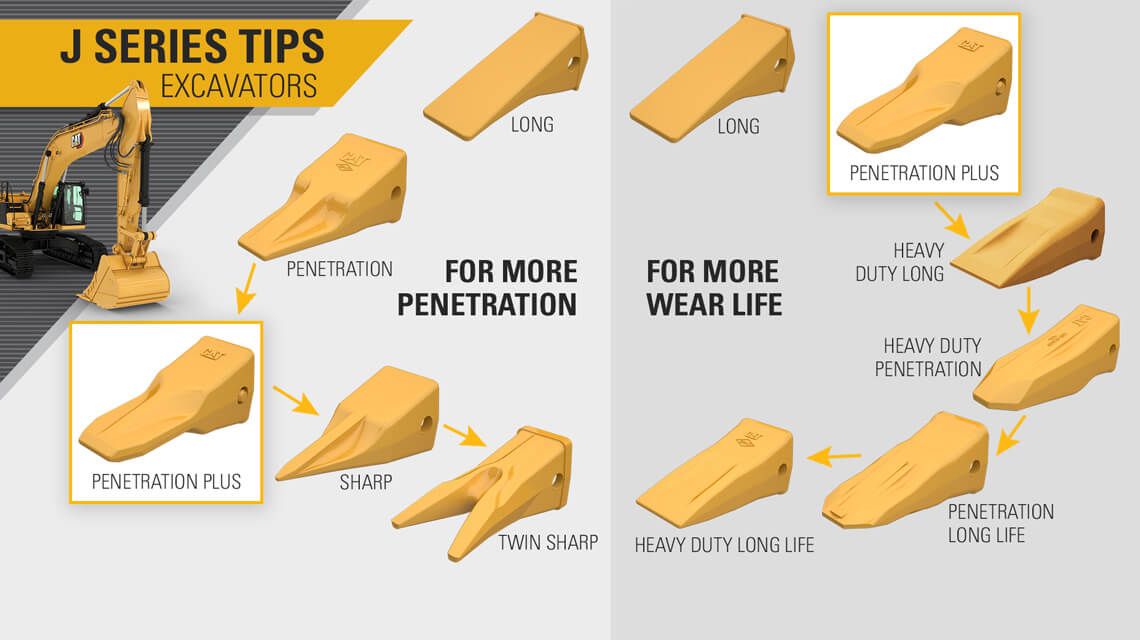

Excavators: Start by considering your application. If you need a good balance between wear, penetration, and strength, Penetration Plus tips are a solid choice. There are many alternatives if you need more wear material or greater penetration.

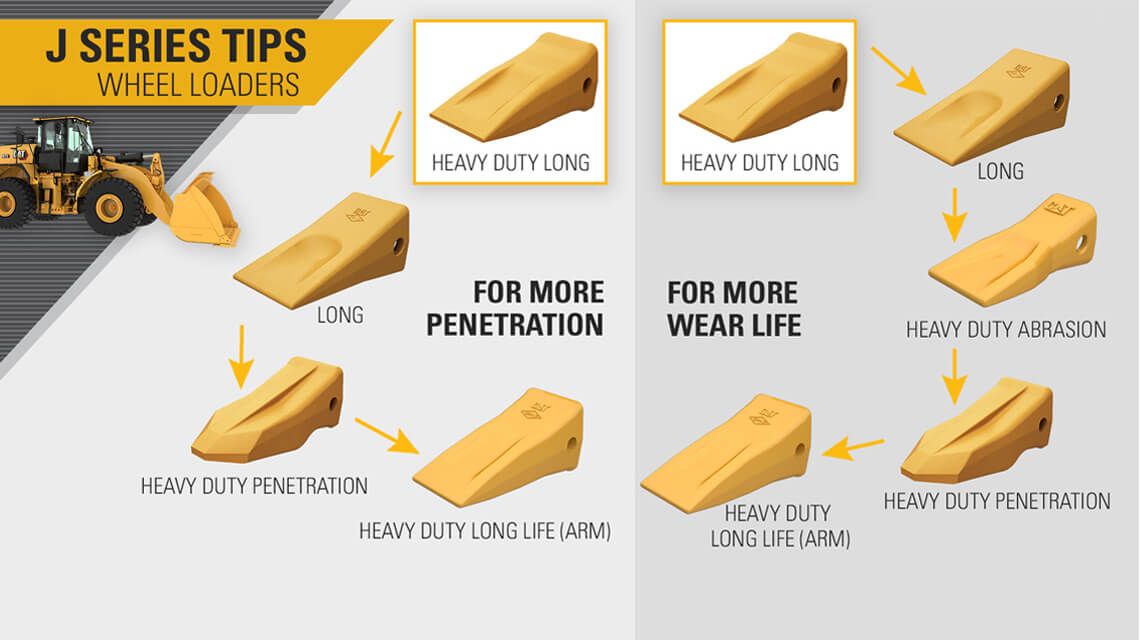

Wheel loaders: Again, consider your application. The Heavy Duty Long tip is commonly used on wheel loaders and works well for a wide variety of tasks. As with excavator tips, you have options if you need more wear material or greater penetration.

If you’re unsure which tip is best for your job, talk to your Cat dealer.

Removing & Installing J Series Tips

Now, let's go over how to remove and install your J Series tips.

Before we dive in, be sure to consult your Operation and Maintenance Manual for safety procedures. Always wear the right personal protective equipment (PPE) when working with these parts.

Step 1: Position the bucket upward before removal. This will keep the tips from falling off.

Step 2: Grab your tooth pin remover and line it up with the right side of the tip. You can get this tool from your Cat dealer or order it through Parts.Cat.com.

Step 3: Hammer the pin remover. Hammer the tooth pin remover until the pin is released, and then remove the tip and retainer. If the retainer is stuck, loosen it by tapping with a hammer.

Step 4: Inspect the adapter. Check the adapter for rust, nicks, or any other damage. Depending on the condition, you may need to repair or replace it.

Step 5: Install the new tip. Once you’ve inspected everything, grab a new pin and retainer. Place the retainer on the adapter, slide on the tip, and insert the pin. Hammer the right side of the pin until it’s fully seated.

With the right tips installed, your machine will be ready to handle whatever the job throws at it. Don’t forget to maintain regular inspections of your tips and adapters to ensure maximum performance and longevity.

To order new bucket tips, or anything else you need for your machine, check out Parts.Cat.com.