If you already have an existing account with another Cat App, you can use the same account to sign in here

One Account. All of Cat.

Your Caterpillar account is the single account you use to log in to select services and applications we offer. Shop for parts and machines online, manage your fleet, go mobile, and more.

Account Information

Site Settings

Security

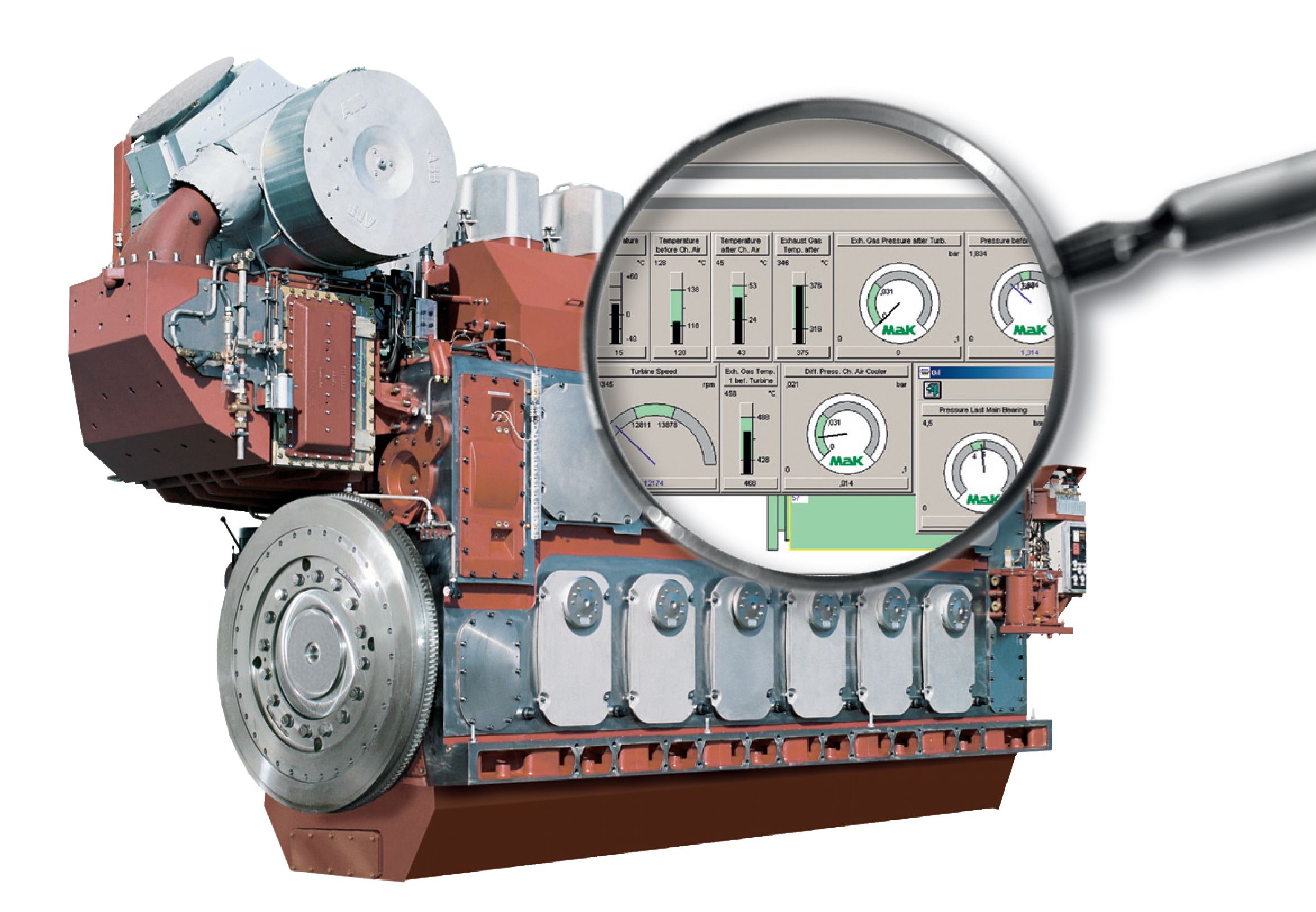

Dicare

System for Diesel Engine Diagnostic and Predicitive Maintenance

The right engines can tell you exactly what they need for long service lives. Cat® and MaK™ engines with MaK DICARE remote engine monitoring software provide reliable, condition-specific maintenance suggestions. DICARE continually compares current engine condition to the desired state and tells you when maintenance is required. You get the diagnostics you need in easy-to-understand words and graphics—the information you need to take action and keep your engines running strong.

By means of accurate information on the current condition and operating mode of the diesel engine DICARE provides for condition-based, adjusted maintenance intervals.

Progress of contamination and wear can be identified at an early stage through trend charts.

For the evaluation DICARE essentially uses installation-specific measuring values.

Current measuring values are compared to the basic protocol with high accuracy. This takes place by evaluating all measuring data at a consistent level according to complex thermodynamic formulas.

By means of different comparison charts and condition-based maintenance recommendations DICARE supports optimum operating conditions.

This allows to enhance service life and provides savings in terms of maintenance and operating costs.

Engine data for evaluation can be fed directly from the engine, imported, or entered by hand in DICARE.

Upon request, the required project specific hardware will be supplied pre-installed and pre-adjusted.

DICARE has been designed for medium-speed engines and allows an evaluation of both Caterpillar and MaK branded engines.

Textual information is supplemented in the program by graphic charts. For multi-engine plants one common display of measuring points where upper or limits are exceeded provides a quick overview of the current performance and condition of the complete plant.

The nominal values calculated precisely for the current operating point and adjusted to the specific ambient conditions can be confronted with the current measuring values in tables for detailed evaluation.

Trend charts of individually arranged groups of measuring values extending over a period of up to 12 months provide an overview to identify slow changes of the operating condition attributable to wear or deposits.

Excerpts from the Engine Diagnostic

- Monitoring of intake air pressure and temperature to identify drops in performance due to turbocharger fouling or wear.

- Early identification of thermal overload through permanent monitoring of all available temperature sensors.

- Monitoring of charge air cooler with regard to pressure loss, charge air temperature, and dew point to identify fouling or misadjustment.

- Check of fuel temperature and viscosity to identify any malfunction of the viscosity measuring and control unit.

- Check of fuel rack position and power output to identify injection pump wear.

- Listing of possible causes of deviations of exhaust gas temperatures from the nominal value.

- Monitoring of lubricating oil consumption to identify any possible wear at an early stage.

- Monitoring of cooling water pressure and temperature to avoid and identify any possible wear.