As part of Caterpillar’s annual product update program, the latest PM620, PM622, PM820, PM822 and PM825 models provide multiple operator comfort, efficiency and equipment management upgrades compared to their previous models.

ST. LOUIS, March 25, 2025 – Offering milling widths from 79.1 to 98.6 in (2010 to 2505 mm), the Cat® PM600 and PM800 cold planer series deliver high-production and efficient performance with the milling precision contractors need to stay competitive. As part of Caterpillar’s annual product update program, the latest PM620, PM622, PM820, PM822 and PM825 models provide multiple operator comfort, efficiency and equipment management upgrades compared to their previous models.

Jameson Smieja

Senior Sales Support Consultant

Cat cold planers

Jameson Smieja

Senior Sales Support Consultant

Cat cold planers

The operator’s workstation is designed for all-day comfort with adjustable consoles, large, cushioned arm rests, hip rests, and optional anti-fatigue floor mats. The center console displays now telescope to bring the touchscreens within easy reach of the operator. Additionally, the displays fold for secure and convenient storage. Available as an option, an adjustable operator control console slides sideways and rotates to further help boost efficiency and reduce fatigue.

A new pedestal seat option allows operators to rest their legs and feet while running the machine. It is designed to quickly and easily retract out of the way when not in use.

The updated machines feature a ladder and gate design that offers unimpeded ascent/descent from the operator platform, and the updated retractable right-side handrail helps to further simplify maneuverability around obstacles. To enhance the operator’s sight lines to the front tracks, the new design incorporates flush-mounted front ground control panels.

Engineered to maximize torque transfer, the PM600 and PM800 series rotor drive system features a heavy-duty dry clutch, automatic belt tensioning system and two high-tensile belts to drive the rotor. A redesigned anti-slab plow delivers improved operation and reduced wear compared to the previous design. Additionally, design upgrades to the anti-slab-to-conveyor sealing help to contain more material to improve milling efficiency and reduce cleanup.

The cold planers’ ground displays now feature a robust mounting system that also enables the ground crew to change mounting locations and store the displays without removing any clamps or electrical connectors. Two rear keypads include controls for leg height, water spray, side plates, moldboard, rear door and steering, while the flush-mount front keypads offer controls for the conveyor, side plates, anti-slab, high pressure washdown, water spray, inboard ski and fuel fill pump.

Available as part of the optional enhanced lighting package, the addition of high-visibility, color LED lightbars replace traditional water level tubes and floats, helping crews easily identify water tank levels day or night and from much farther distances. The touchscreen displays automatically change to night mode when working lights are activated to help improve visibility.

The PM600 and PM800 cold planers series now come standard with Cat Remote Services technology to help improve machine diagnostics and operating efficiency when within cell range coverage. Remote Troubleshoot allows the Cat dealer to perform diagnostic testing on the connected machine, enabling the technician to pinpoint issues while the mill is operating, so they arrive with the correct parts and tools the first time. Remote Flash enables contractors to update onboard software without the need for a technician, so updates can be initiated at a convenient time without interrupting production.

Optional productivity features of VisionLink®, now available with a VisionLink PerformancePro subscription, help contractors measure, monitor and manage the cold planers to maximize productivity on or off the jobsite. Critical, actionable machine operating data, such as wait time for trucks, time spent cutting and maneuvering around the jobsite, as well as distances cut, fuel burned, and detailed cycle location mapping, is transmitted from the jobsite to the VisionLink web platform for users to access anywhere an internet connection is available.

The Cat Inspect mobile application tool enables operators and technicians to quickly perform digital preventative maintenance checks, inspections and daily walkarounds.

Caterpillar began manufacturing cold planers in 1992 with the introduction of the PM-565, which boasted features such as non-contact grade sensors, microprocessor control for propel response and self-diagnostic computer monitoring. Today, Caterpillar manufactures eight cold planer models in Minerbio, Italy.

More information on the design upgrades for Cat PM600 and PM800 cold planer models can be found by contacting a Cat dealer or visiting cat.com.

Model |

PM620 |

PM622 |

PM820 |

PM822 |

PM825 |

Engine |

Cat® C18 |

Cat® C18 |

Cat® C18 twin-turbo |

Cat® C18 twin-turbo |

Cat® C18 twin-turbo |

Emissions, Highly Regulated Countries (HRC) |

U.S. EPA Tier 4 Final, EU Stage V, Korea Stage V |

U.S. EPA Tier 4 Final, EU Stage V, Korea Stage V |

U.S. EPA Tier 4 Final, EU Stage V |

U.S. EPA Tier 4 Final, EU Stage V |

U.S. EPA Tier 4 Final, EU Stage V |

Emissions, Lower Regulated Countries (LRC) |

Brazil MAR-1, equivalent to U.S. EPA Tier 3 and EU Stage IIIA |

Brazil MAR-1, equivalent to U.S. EPA Tier 3 and EU Stage IIIA |

U.S. EPA Tier 2, EU Stage II equivalent |

U.S. EPA Tier 2, EU Stage II equivalent |

U.S. EPA Tier 2, EU Stage II equivalent |

Gross Power (SAE J1995), HRC |

474 Kw |

474 kW |

601 kW |

601 kW |

601 kW |

Gross Power (SAE J1995), LRC |

470 kW |

470 kW |

576 kW |

576 kW |

576 kW |

Engine Power (ISO 14396), HRC |

469 kW |

469 kW |

595 kW |

595 kW |

595 kW |

Engine Power (ISO 14396), LRC |

464 kW |

464 kW |

569 kW |

569 kW |

569 kW |

Operating Weight, HRC |

31 559 kg |

32 035 kg |

34 088 kg |

34 565 kg |

35 175 kg |

Operating Weight, LRC |

30 815 kg |

31 291 kg |

33 504 kg |

33 980 kg |

34 950 kg |

Transport Weight, HRC |

30 330 kg |

30 806 kg |

32 859 kg |

33 336 kg |

33 946 kg |

Transport Weight, LRC |

29 586 kg |

30 062 kg |

32 275 kg |

32 751 kg |

33 361 kg |

Cutting Width |

2010 mm |

2235 mm |

2010 mm |

2235 mm |

2505 mm |

Cutting Depth |

330 mm |

330 mm |

330 mm |

330 mm |

330 mm |

Overall Length (conveyor raised) |

14.52 m |

14.52 m |

14.52 m |

14.52 m |

14.52 m |

Maximum Machine Width |

3.11 m |

3.11 m |

3.11 m |

3.11 m |

3.11 m |

Maximum Height (conveyor raised) |

5.23 m |

5.23 m |

5.23 m |

5.23 m |

5.23 m |

# # #

About Caterpillar:

With 2024 sales and revenues of $64.8 billion, Caterpillar Inc. is the world’s leading manufacturer of construction and mining equipment, off-highway diesel and natural gas engines, industrial gas turbines and diesel-electric locomotives. For 100 years, we’ve been helping customers build a better, more sustainable world and are committed and contributing to a reduced-carbon future. Our innovative products and services, backed by our global dealer network, provide exceptional value that helps customers succeed. Caterpillar does business on every continent, principally operating through three primary segments – Construction Industries, Resource Industries and Energy & Transportation – and providing financing and related services through our Financial Products segment. Visit us at caterpillar.com or join the conversation on our social media channels at caterpillar.com/en/news/social-media.html.

NOTE TO EDITORS: Caterpillar rolls out products and services in each of its regions at different time intervals. Although every effort is made to ensure that product information is released only after Caterpillar has received confirmation from its independent dealer network, plants, and marketing subsidiaries that products and services are available in the relevant region, editors are kindly requested to verify with a Cat dealer for product availability and specifications.

CAT, CATERPILLAR, LET’S DO THE WORK, their respective logos, “Caterpillar Corporate Yellow,” the “Power Edge” and Cat “Modern Hex” trade dress, as well as corporate and product identity used herein, are trademarks of Caterpillar and may not be used without permission.

VisionLink is a trademark of Caterpillar Inc., registered in the United States and in other countries.

Caterpillar launches the next generation design for the Cat® 321, 322 and 324 models, built to deliver high performance, long-lasting durability and increased fuel efficiency.

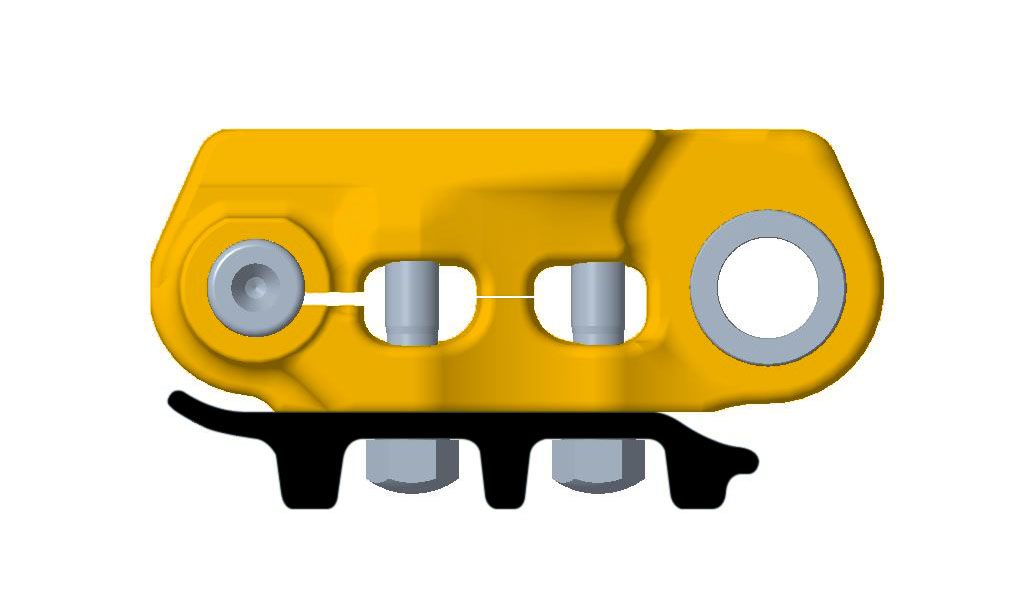

Learn MoreIt’s all about getting back to work quicker with the new Cat® Track Clamp Master Link assembly, designed to improve track installation efficiency in the field by eliminating the need for a portable field press.

Learn MoreThe best machine operators across North America gathered in Clayton, NC to forge their legacy and prove their mastery of both equipment and technology.

Learn MoreCaterpillar is announcing its new Cat® 140 LVR Motor Grader, upgrading it to the next generation platform.

Learn More